|

Group DF - international group of the companies, major investments are concentrated in the nitrogen, titanium and gas businesses. |

|

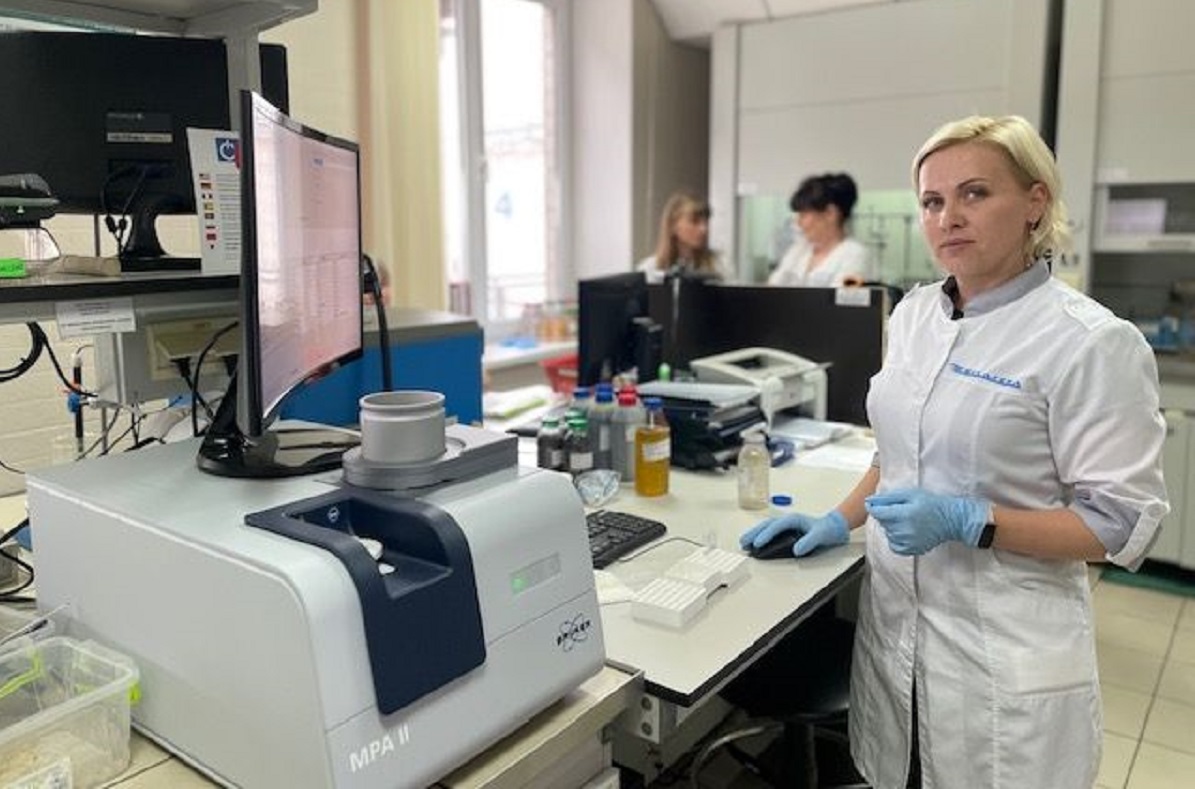

11 June 2021 Nika-Tera seaport laboratory will allow to analyse agricultural cargoes in 1 minuteNika-Tera seaport, a member of Group DF, upgraded the laboratory to increase the speed of analysis of agricultural consignments: vegetable oils, sunflower meal and cereals. The laboratory is equipped with the automated spectrometer FT-NIR MPA II Multi Purpose Analyzer, produced by Bruker Optics (Germany), which costs more than UAH3,000,000.  Bruker is a public company listed on NASDAQ. The company specializes in the production of diagnostic solutions and equipment that allow to study materials at the molecular, cellular and microscopic levels.

The launch of new equipment in the seaport laboratory will significantly increase the speed and accuracy of the quality analysis of the incoming cargo. Whereas the arbitration analysis used in most laboratories takes up to two days and is associated with risks, similar analyses in Nika-Tera seaport will take a minute. New innovative equipment allows you to quickly detect damage or counterfeiting when receiving goods and to accurately determine the quality of the product.

Dmytro Firtash’s Group DF invested more than UAH1.5 billion to develop the seaport. As a part of the program designed to increase the seaport throughput capacity, the following was done:

|